Lower maintenance costs:

Inverter against tamping on pumps

The water supply and wastewater disposal company Hamburger Wasser is increasingly using frequency converters for the pumps in its wastewater network. This is because the lower rinsing water volumes with increasing solids content make an intelligent actuator necessary. In the Randersweide pumping station, the converter’s backwash mode saves the previously very often necessary dejamming operations due to clogging.

The initial situation: This is how Hamburg's wastewater flows

Hamburg Wasser is the water supply and wastewater disposal company for the citizens of Hamburg. Around two million people are currently connected to the company’s network. In addition to producing and treating drinking water, Hamburg Wasser also treats the Hanseatic city’s wastewater. Here, the utility has one goal: realize lower maintenance costs at the pumping stations. This will simultaneously ensure the safe operation of wastewater management in the Hanseatic city.

Hamburg’s wastewater flows through a network of pipes some 5,800 kilometers long. The house pipes through which the wastewater enters the public sewer system have a diameter of only about 15 centimeters. The public sewers are usually two to five meters deep underground and up to 150 centimeters high. Even larger channels, the transport stems and collectors and the older Hamburg stem stems run at depths of up to 27 meters and can be up to 4.7 meters wide and 3.85 meters high. Unlike the street sewer system, these transport sewers do not have a connection to surface waters, but lead – mostly in a free fall – directly to the Hamburg wastewater treatment plant.

Transport pipes and collectors have the task of relieving the local sewer system, especially during rainfall, and thus protecting against water overflowing onto properties and into watercourses. The construction of underground combined sewer retention basins also serves to relieve the sewer system when it rains: if the sewers are full, the water runs into the retention basins via so-called overflows. There it is temporarily stored and only when the sewer system is able to absorb it again is it returned to the system by automatic pumps or by free fall.

By loading the video, you agree to YouTube's privacy policy.

Learn more

No more old habits ...

In this Danfoss video podcast, Michael Rix from Hamburg Wasser tells how the Hamburg water utility uses the integrated backwash function of the VLT® AQUA Drive frequency converter to remove clogging and other debris from pumps in its wastewater plant and reduce maintenance costs.

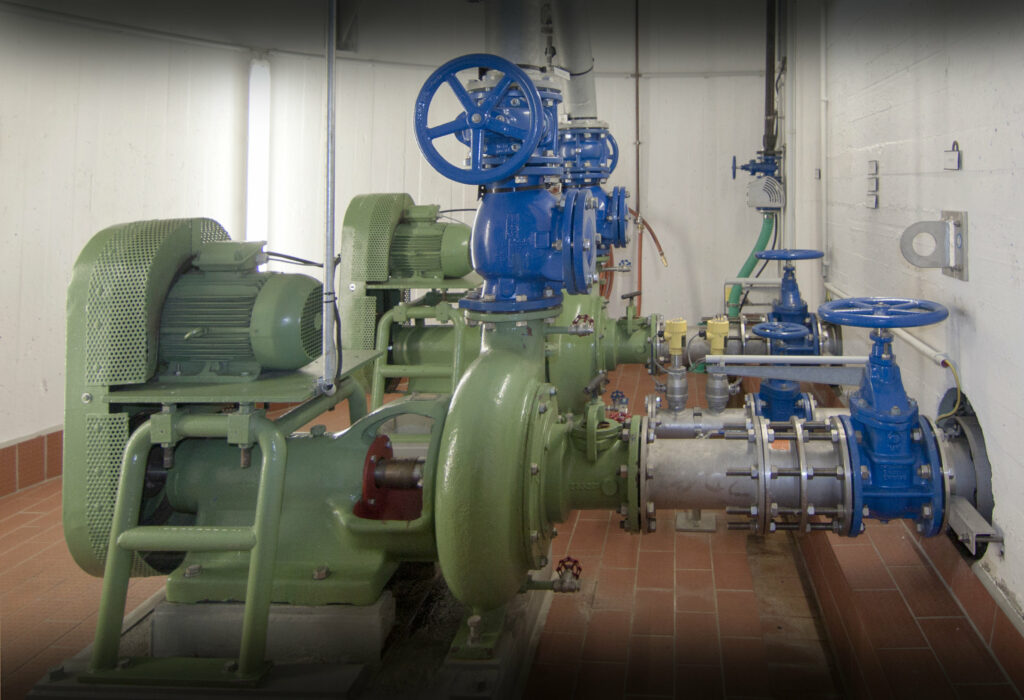

Randersweide pumping station: lower maintenance costs the goal

Since the wastewater contains many substances, from hair to bags to cleaning rags, many things float in the water that do not actually belong in it, the pumps used have a correspondingly difficult life. The increasing viscosity of wastewater led to more and more critical operating conditions in wastewater pumping stations at Hamburg Wasser: Particles and fibers contained in the water were deposited on the impellers, leading to reduced performance and excessive wear in the pumps.

The Randersweide pumping station was recommissioned after refurbishment in 2014. As a result of the increased inflow due to numerous new buildings in the catchment area, there were 39 pump clogging interventions here in the year after recommissioning. Servicing a clogged pump takes a lot of time, from getting to the site and lifting the pump to cleaning and reinstalling it. In this respect, the many failures caused high costs. A solution had to be found for this.

As the problem continued to grow, the first step was to try to optimize the pump level. In addition, an attempt was made to run the pumps in reverse manually via the control center after a malfunction was reported. Unfortunately, not always successful, because the pumps were then already strongly verzopft. Hamburg Wasser’s Operations Engineering department therefore began searching the market for an automated solution. The aim was to have the pumps rotate backwards reliably and automatically via a frequency converter while at the same time operating economically.

Makes money liquid: Backwash mode

Fouling of impellers in sewage pumps due to deposits or tangles is a general problem because the performance of the pump is reduced and it can become blocked. That is why the VLT® AQUA Drive has a backwash mode as standard, which reverses the direction of rotation of the impeller, thereby loosening deposits on the impeller. Since not every type of pump can be counter-rotated, the operator must consult the pump manufacturer before using this function.

When starting a backwash cycle, the drive first ramps to a stop, then runs a shutdown delay before starting the first cycle. If the backwash mode is triggered by a stopped state of the frequency inverter, the first switch-off delay is skipped. The backwash event can consist of several cycles. One cycle consists of one pulse in reverse followed by one pulse in forward. The backwash process is complete after the specified number of cycles have been completed. Between the pulses, the frequency inverter switches to freewheeling for the specified switch-off delay time so that the residues can settle in the pump.

Backwash mode: Individually adjustable to the application

The backwash mode can be individually parameterized to the experience values of a user with his plant by configuring delay times, backwash speed as well as performance monitoring. The user determines how often, how fast and how long the frequency converter should rotate the impeller in the opposite direction at start or stop, timer controlled by means of digital input, by means of serial communication or using a set of programmable logic rules.

Another approach is reactive cleaning. Here the frequency converter initiates cleaning as soon as the pump draws more energy from the frequency converter than it normally should. At this stage, the pump is already beginning to bog down. The user can combine the functions for proactive and reactive cleaning.

In Randersweide, energy saving effects are not in focus due to the high full load times of the pump and the already low output of 9.2 kW. On the other hand, the Drive Controller provides considerable added value through the extended data acquisition of condition and motor data via value corridors. First and foremost, however, the integrated backwash function of the Aqua Drive is having a positive effect: Whereas the maintenance team previously had to call out four times a month, the number of calls to remove blockages has fallen to zero so far with the use of the Aqua Drive. This means that Hamburg Wasser, as the operator, calculates that the purchase of the frequency converters for 5800 euros has clearly paid for itself through the saved costs of 7500 euros in a period of 6 months.

Mission accomplished: Lower maintenance costs in Randersweide

By optimizing the system to enable the backwash function, Hamburg Wasser is making significant savings in maintenance and repair costs at the Randersweide pumping station and also increasing the pump’s uptime. This and the extended monitoring options in the direction of the pump and motor make it easy to get over the minor energy disadvantage. It is worthwhile in any application where tarnishing occurs repeatedly and high operational reliability is important to take a close look at the issue and, if necessary, to use the backflush function in a preventive and reactive programmed manner. Even if energy saving effects should not be given by the speed control.