Semiconductors in the home: How converters benefit from the e-car

Episode 5

Innovative power electronics -

Why frequency converters benefit from electric cars

In the past, industry has been the driver of innovation in power electronics. Today, it is the automotive industry that is driving innovative power electronics. In this episode of Drehmoment – Der Antriebspodcast, Ole Mühlfeld from Danfoss Silicon Power and Norbert Hanigovski from Danfoss Drives explain how frequency converters can also benefit from this.

What Hanigovski appreciates most about the partnership between the two companies, apart from the technology, is the security of supply. Danfoss Silicon Power is an independent company and a major supplier to various industries. Because the company is chip-independent, managers can protect customers from supply bottlenecks. The frequency converters also benefit from this.

Stable supply chain for innovative power electronics

Many economists and management consultants are talking about resilience these days. It is a buzzword of the crisis, the resilience of companies is to be invoked. It’s all about solid finances and stable supply chains – especially from Asia. After the crisis, things could change, some say, and new supply chains are on the horizon. Really?

Norbert Hanigovszki of Danfoss Drives was relaxed in the spring of 2020 and continues to be so in the fall of 2020. "We have a very secure supply chain because we buy our power electronics from Danfoss Silicon Power." He laughs. The Danfoss company works chip-independently, can install different chips and is thus an exception in Europe. "I’m always an A customer, never a C customer," Hanigovszki emphasizes – even if his industry is no longer setting the pace for technology development.

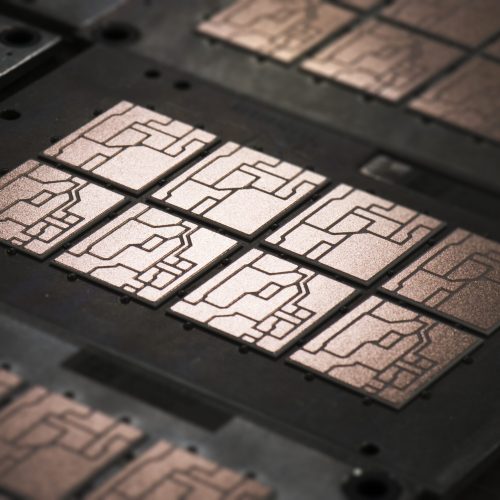

The power electronics switch the current flow on and off – in simplified terms. In addition, it shapes the storm through pulse patterns and ensures that a DC voltage becomes an AC voltage. "Norbert’s software is the brain of the frequency converter. We are the heart muscle," emphasizes Ole Mühlfeld from Danfoss Silicon Power.

The happy automotive supplier

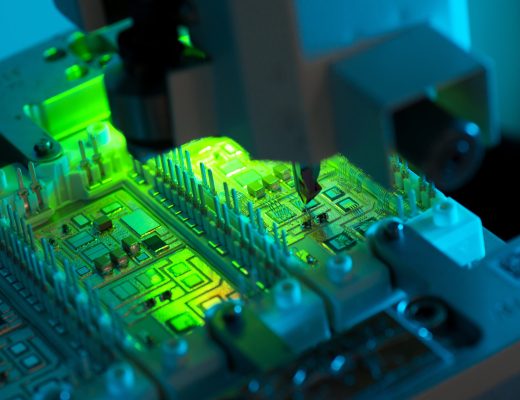

But stationary applications, like drives in factories, are not where the future of Danfoss Silicon Power’s power electronics lies. Hanigovszki also has to acknowledge that. "The automotive industry is becoming an important customer," confirms Mühlfeld. We are talking about unit sales of over 100,000 units. "Electrification demands new technology in automotive power electronics." Mühlfeld and his more than 100 colleagues in development are the happy automotive supplier. They have become rare in 2020.

And the stationary applications? "The most important thing in the automotive industry is reliability. In cars, we have to deal with high temperatures and vibrations. What Ole and his colleagues develop there, we also benefit from," Hanigovszki is convinced. Mühlfeld agrees, saying, "We’ve brought shower power cooling technology from the wind energy sector to automotive traction, and we’ll soon see new developments from the automotive industry flow back into stationary applications."

Up to seven percent more range

One source of hope: silicon carbide. The compound semiconductor promises efficiency and faster circuits. But Hanigovszki warns: "This can also quickly destroy the engine. In regenerative operation, however, the technology plays out its advantages to the full." In the end, he said, you always have to look at where you use which technology. "The semiconductors have high switching edges. That makes for displacement currents that can cause damage. But we can also control these semiconductors with a resistor, for example."

Eanother parameter is important to him: "Manufacturers of electrical machines will adapt to the new technology. Developers are changing designs to work with the higher switching speeds." Ahe automotive industry is also a pioneer in this area. "OEMs are adapting. The driver is customer demand for more electric range. Five to seven percent can be extracted with silicon carbide."