Energy from wastewater:

How does the energy self-sufficient wastewater treatment plant work?

Episode 9

The energy self-sufficient wastewater treatment plant from Aarhus

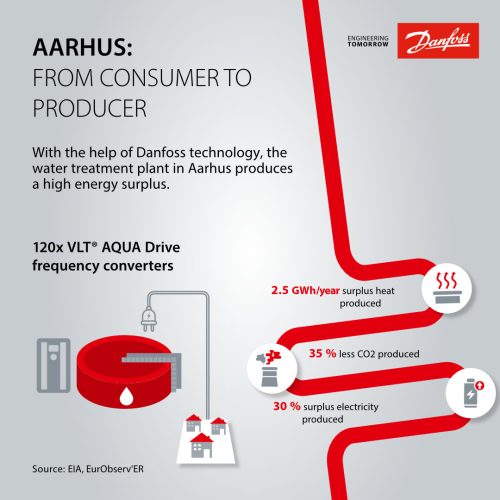

The energy self-sufficient wastewater treatment plant of tomorrow already exists today. It is located in Aarhus, Denmark and inspires water management worldwide. The Danish municipality operates this CO2-neutral wastewater treatment plant and saves a lot of energy in the process. This is because water and wastewater management normally accounts for 30 to 50 % of the electricity consumed by municipalities in Europe. There is a lot of potential for improvement – in Europe and worldwide.

Claus Homann is responsible for wastewater management in Aarhus and is proud of his team. Together with Mads Warming from Danfoss Drives, they have achieved a lot in the last 10 years and converted the existing plant into one of the most modern wastewater plants in the world. Before its conversion, the plant was not very different from other existing wastewater treatment plants. This gives confidence to many other operators! What do you need to do to make an existing plant fit for a green future? How the two experts managed to do this and why other plants in Europe can also benefit from it, is revealed in this episode of Torque – The Drive Podcast.

Read the full case story here.

How did they do that? An interview with Claus Homann and Mads Warming

Claus Homann: I think we are a good example because on the one hand we save a lot of energy and at the same time we produce energy as a wastewater treatment plant. And that is fantastic.

What are the differences to existing plants in Europe? What did Aarhus do differently?

Claus Homann: The plant itself is not very different from other existing wastewater treatment plants. Rather, it is the people who work there every day and have internalized the goal of saving energy and CO2. Back in the 1990s, we started thinking about how we could save energy and then went in search of technologies.

Is Aarhus unique?

Mads Warming: There are a few other plants in the world that operate similarly to Aarhus and have the same goal. However, it is also important to understand that unlike these plants, energy in Aarhus is generated only with household wastewater – not with additional waste from, for example, the food industry or from solar panels or wind turbines. This is the unique selling point of Aarhus. And that is why the example is so good for other wastewater companies, because the effort is manageable.

What has been technically optimized?

Claus Homann: We expanded people’s mindset, developed a vision with them and created an incentive system. You may invest in new technologies. But it’s about motivation. We also sent the colleagues to other plants, they were supposed to learn and develop ideas.

The most important thing is automation. We have been working with automation and SCADA systems for years and this allowed us to feed our knowledge, our data into the systems – 24 hours, 365 days a year. This is important in order to achieve our goals. And of course we have frequency converters on almost every pump. In addition, we use anammox, have optimized the ventilation and renewed the drainage units. These investments paid off after four and a half years.

Nothing more - a few frequency converters and then it runs?

Mads Warming: I would like to highlight automation, which we often call digitalization today. The sensor system in the plant is important, because it drives the wastewater treatment plant at night. And many customers confirm this, because 70 percent of the progress made in recent years is based on the automation or digitization of processes.

What is behind this 70 percent progress through digitization?

Mads Warming: For me, digital means data and information from many sensors, more than are usually installed. Users need to use this data for more analysis than they have in the past. That’s exactly what Claus and his colleagues do. They have a lot of sensor signals and know much better what is happening in the plant. Sensors and control are the keys to success.

How many new sensors do you have in the plant?

Claus Homann: We have many and we buy every one that helps us further in wastewater treatment, saving and producing energy. The user must be willing to invest in the sensor technology, because some sensors are quite expensive. There was a lot of uncertainty when it came to handing over control of the plant to the computer. We therefore rely on a three-tier system. The starting point is the standard wastewater parameters and then users can run the plants at a higher quality level with a digital twin. And because we keep falling back on standard wastewater parameters, operators are confident in testing new processes.

This means that the colleagues initially drive process changes with the digital twin of the plant?

Mads Warming: I’m sure Claus can explain that better, but I want to add something: You control and manage the core task of purifying water. But the ability to know what the ammonium level is changes the operation again. This allows users to drive the process with more information. For example, you can slightly increase the ammonium content to save energy, depending on the current price of electricity or depending on government payments if the ammonium content is reduced. You can play with the settings and adapt to external factors.

You praise sensors, but Danfoss doesn’t sell sensors.

Mads Warming: Without the AC drives, Claus could perhaps only save a third of what he and his team are currently achieving. Wastewater treatment plants follow a different rhythm compared to, for example, chemical plants: they have a peak of material in the morning, then again in the afternoon, and only about 10 or 20 percent material at night. Still, operators must run the plant 24/7. The more sensors are installed, the better they know what the load is at any given time and can align the systems accordingly.

What about the other 30 percent? How important are pumps etc. for more efficiency?

Claus Homann: Pumps etc. are important. But an efficient pump does not do the whole trick. We are too often focused on individual energy-efficient devices. But it’s about improving existing processes and not just replacing individual pieces of equipment. The overall perspective remains decisive.

So a holistic approach?

Mads Warming: Yes absolutely, we have to look at the whole plant down to the ammonium. I fully agree with Claus. The task is to work on the corporate culture – with the people in the wastewater treatment plants. We have to have the operators on board or we won’t achieve our goals. The obstacle is that legislative initiatives on energy efficiency from Brussels rarely look at the system. So far, for example, it’s all about the engines. That’s okay, but, to put it bluntly, it only brings about one percent gain in efficiency. We are talking with Claus today about 70 to 80 percent.

How high is the savings potential worldwide?

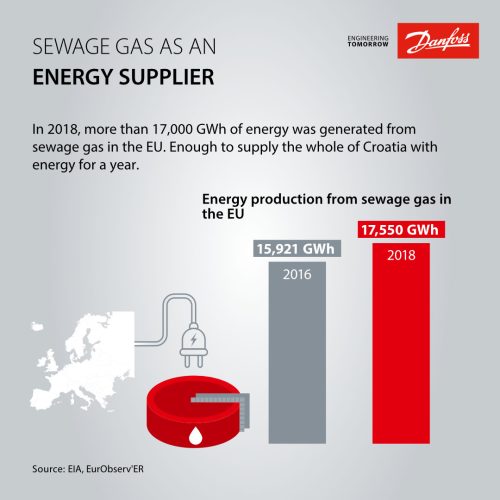

Mads Warming: We have been working with the International Energy Agency for a number of years. Once a year, it publishes a thick 700-page book on where energy comes from and who uses it. And the authors also present analysis and information on potential savings. Water and wastewater treatment accounts for 3.5 percent of Europe’s total electricity consumption. Globally, the figure is four percent. This is equivalent to the electricity consumption of Russia.

If everyone would copy Claus’ approach, it would have a great effect. By 2030, 60 percent of the world’s wastewater will be treated. This means that some new wastewater treatment plants will have to be built. This figure has worried the International Energy Agency, because it means that energy consumption is also increasing. We invited the responsible parties to Aarhus and were able to convince them that both goals can be achieved – energy savings and clean water for the environment and people.

And again, we don’t have to shut down existing plant. In Aarhus, the ROI is 4.5 years. The price of electricity in Germany is even higher, so the investment there pays off even faster. It not only makes ecological sense, but is also economically feasible.