Safe drinking water supply

in the region Nahe-Glan

The supply of drinking water – this is where the highest reliability is required. Verbandsgemeindewerke Nahe-Glan relies on Danfoss DrivePro Site Assessment for maximum availability and better planning during maintenance and service. For this purpose, the service technicians of our partner Klebs+Hartmann take a close look at all frequency converters in order to carry out a risk analysis based on this and provide recommendations for action to ensure a safe drinking water supply.

1 million cubic meters of safe drinking water supply

Verbandsgemeindewerke Nahe-Glan supplies 18 local communities and the city of Bad Sobernheim with the important foodstuff drinking water. The annual water consumption amounts to approx. 1 million m³, which flows via approx. 6,900 connections to approx. 18,500 inhabitants. Drinking water is pumped from 26 extraction plants, i.e. 23 deep wells, 1 industrial well and 2 springs, through 13 UV plants to the storage plants and from there it is delivered to households. Due to the topographical location, 4 pumping stations, 3 booster stations and 12 pressure reducing stations are in use to provide normal water demand and water pressure. From 22 elevated tanks, the water makes its way to the consumers through an approx. 250 km long pipeline system. At numerous points in this system, frequency converters contribute to the region’s safe drinking water supply.

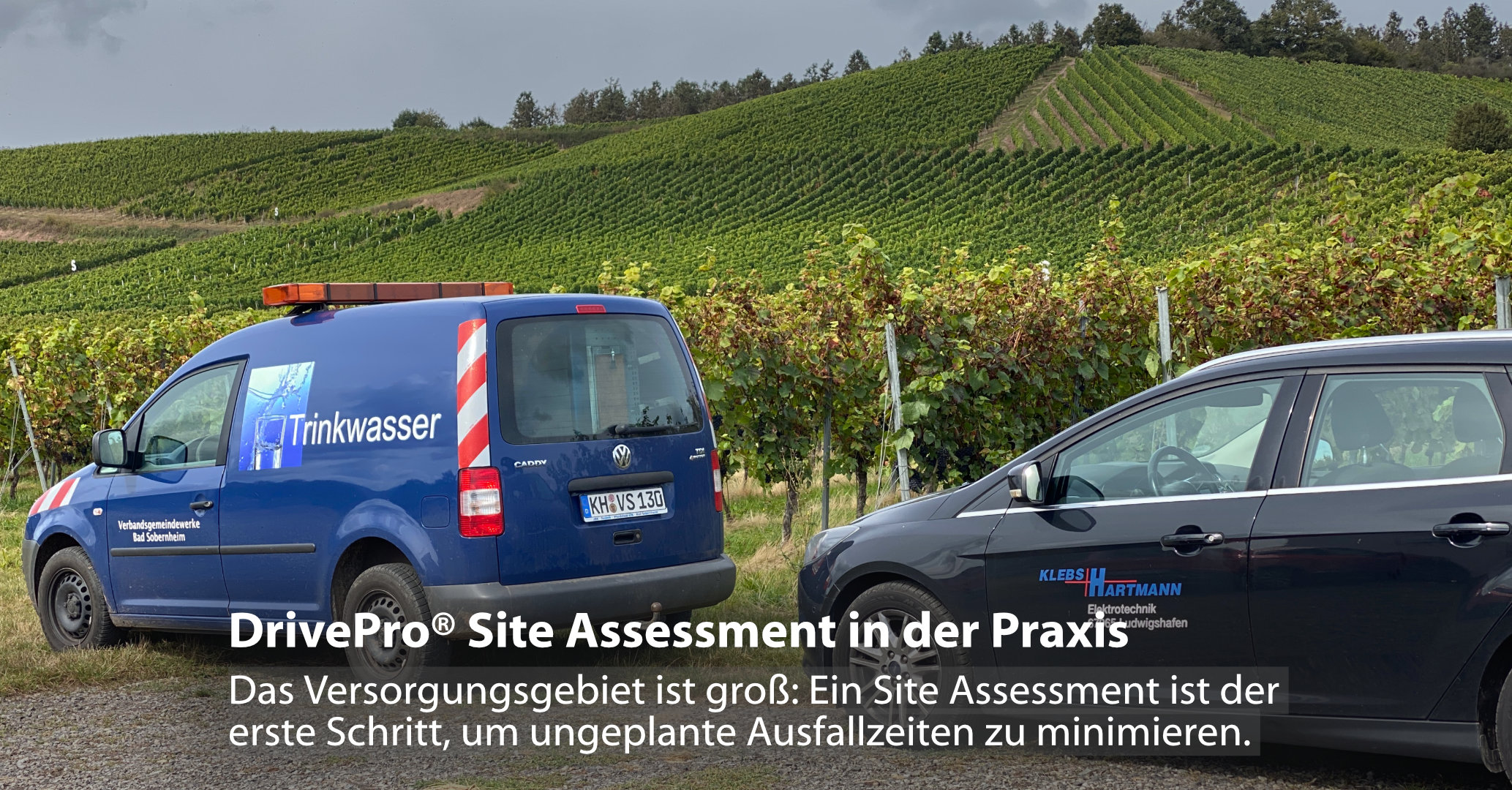

It is the end of October 2021. The day promises to be sunny. All the better, because today a lot of work in the fresh air awaits salesman Jürgen Hedderich and service technician Ralf Schütz from Danfoss partner company Klebs+Hartmann. The two experts travel from the company headquarters in Ludwigshafen am Rhein in the morning to meet Rüdiger Eckel from the drinking water supplier VG Nahe-Glan in Bad Sobernheim. A DrivePro Site Assessment, which is an inventory and evaluation of all variable frequency drives in a facility, is on the schedule. The experts carry the little equipment necessary for this job in their trunks.

First of all, they go through the pre-arranged schedule for the day with Eckel again. It quickly becomes clear that today will be a long day for the three technicians. On the one hand, the stations in which the frequency converters are in service are far apart, and on the other hand, a large number of converters have to be inspected and recorded for the inventory. The vast majority of them control the pumps in the region’s water supply network.

DrivePro Site Assessment: Small blood count for the frequency inverter

Technicians Hedderich and Schütz are excited to see what old treasures and surprises they will find during today’s DrivePro Site Assessment at VG Nahe-Glan. This special service also always feels a little like a Treasure hunt on. Why? Alexander Bladowski from Danfoss Drives knows this very well. When he inspects the frequency inverters in his customers’ plants, he sometimes finds an older device that is no longer known or for which spare parts are no longer available – a real treasure.

Of course, such treasures are valuable, but they can suddenly fail, disrupting smooth operations. Nobody needs that! How good that plant operators can initiate countermeasures at an early stage, for example with a DrivePro Site Assessment. This complete, site-wide coverage and risk assessment of all AC drives enables operators of critical infrastructure assets to optimize their maintenance strategy. "A DrivePro Site Assessment is like a little blood work for a company’s AC drives that you can then build on," Bladowski explains. Because if users know their values, they can build their strategy solidly on them. This minimizes unforeseen plant shutdowns and sudden disruption. Bladowski explains exactly what is behind a DrivePro Site Assessment from Danfoss Drives in a video interview.

Commitment with a view to safe drinking water supply

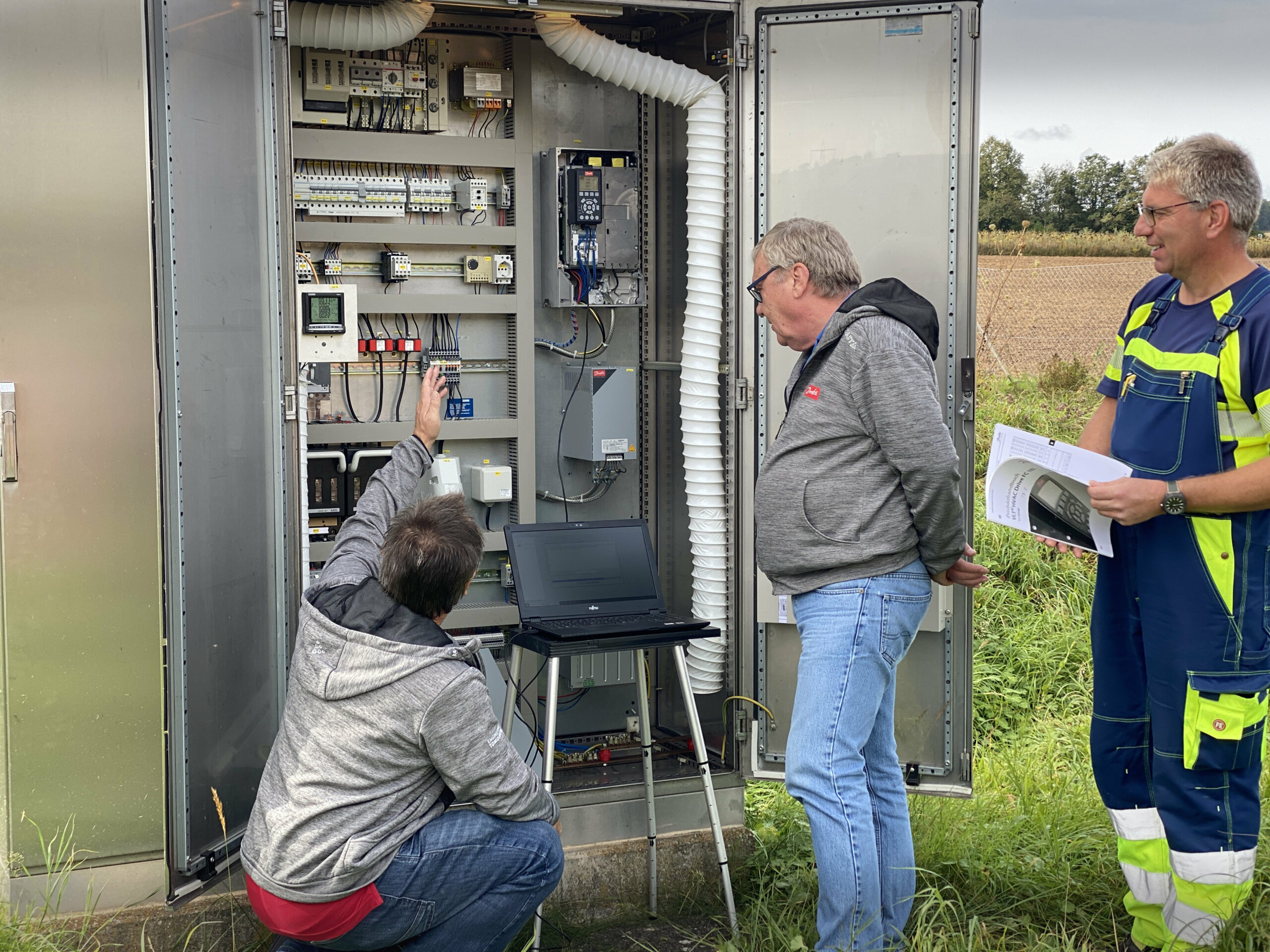

Back on site in the Bad Sobernheim region. After the short vote, we go straight to work. Eckel knows his work area like the back of her hand and unerringly heads for the first pumping station on her list. Once there, the two existing VLT 6000 frequency converters from Danfoss Drives are checked and their data transferred to a service laptop. They are then evaluated in the next step as part of a risk analysis. Today, however, is all about taking stock. The two technicians will provide the exact analysis and suggestions for possible measures in a few days after the inventory.

In addition to the actual DrivePro Site Assessment, the Danfoss partner also offers a cloud service: If desired by the plant operator, the data can be stored in a company-owned cloud. In this way, the user can access the stored parameters of the frequency inverters 24/7. And if a failure does occur, this reduces the downtime considerably. A replacement device can be delivered quickly and correctly parameterized.

Good reasons for a site assessment in drinking water supply

Now it goes on from plant to plant. The goal is to record the data of all frequency converters today and then evaluate it in the next step in order to take appropriate measures. Because if the plant operator knows the actual condition, the risk of failure and downtimes can be minimized and maintenance can be planned in a targeted manner.

Rüdiger Eckel from Verbandsgemeindewerke Nahe-Glan knows exactly why he opted for this service: "Since our plants are distributed throughout the region, we want to use the Site Assessment to optimize our maintenance strategy and protect ourselves against unplanned outages; especially with a critical infrastructure such as drinking water supply, it is important to always be precisely informed about the condition of the plants so that we can intervene at an early stage."

Jürgen Hedderich can reassure Eckel for today: "Here at VG Nahe-Glan, the frequency converters are in good shape and also neatly housed – we have seen quite different things. Still, it’s worth taking stock of the equipment. That way you’re prepared for any eventuality."

How did they do that?

In the video interview, Jürgen Hedderich talks about the assignment at VG-Werke Nahe-Glan. "During a site assessment, we record a wide variety of inverter data. In this way, the operator can very easily obtain a complete overview of the lifecycle status of all frequency converters and prevent unexpected maintenance measures." This holds added value especially for critical infrastructures such as the safe drinking water supply in the Nahe-Glan region.