Which frequency inverter fits your motor?

Motor technology - highest efficiency through optimum control

Much has happened in the development of engine technology in recent years. Not least due to legal requirements for the minimum efficiency of electric motors in plants, permanent magnet and synchronous reluctance motors have also become established on the market in addition to the classic standard asynchronous motors. The latter motor types in particular are characterized by maximum energy efficiency – but, with the exception of some special designs, they always require a controller to operate them on the three-phase mains. The aim is always to set the motor parameters so that the motors run at the best possible operating point at all times. NTT Global Data Centers EMEA GmbH relies on these synchronous reluctance motors for its pumps, which offer very high energy efficiency. Especially in the present application, the data center operator can achieve a further cost reduction in addition to the cost reduction through converter operation.

Total package or optimized components?

Some motor manufacturers only offer their motors in combination with their own frequency inverter on the grounds that these combinations offer the best possible efficiency and thus maximum efficiency. However, individually assembled packages of motor and frequency converter can also achieve at least equivalent, if not better, efficiency values.

Danfoss, for example, as an independent manufacturer of frequency converters, offers high-quality control algorithms that achieve peak energy efficiency values with all motors on the market. Each of the Danfoss frequency converters supports all common motor technologies on the market.

Maximum energy efficiency requires optimized control algorithms

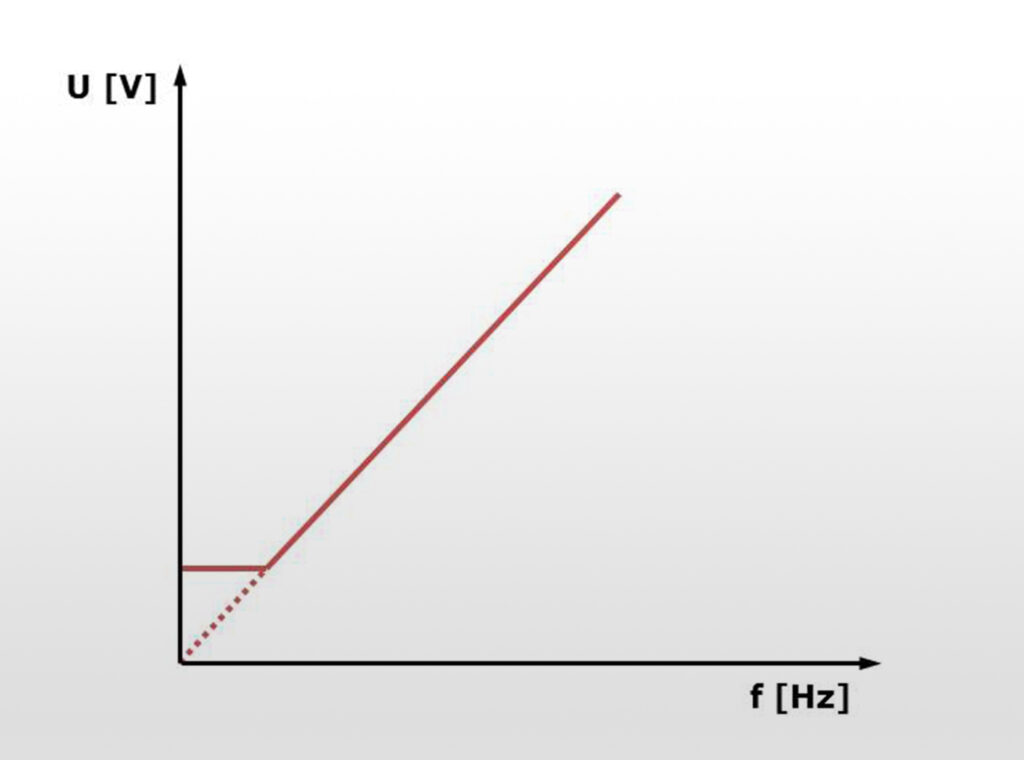

In principle, almost all motors can be driven with a fixed programmed curve that specifies the necessary voltage for a speed or frequency, the so-called V/f characteristic. However, only control algorithms specially adapted to the respective engine technology guarantee the efficiency advantages of the individual technologies. Only with these algorithms can operation be optimized at every operating point, even with changing loads.

And this is precisely the challenge when only one type of frequency inverter is required to optimally drive the various motor technologies for all load cases, in all power ranges and operating points. How can a control algorithm be optimized for this, what information does it need, and what strategies should be used to design voltage and frequency for maximum motor efficiency? This is where the know-how of the manufacturer of the control electronics is required.

The state of the art for controlling motors today is vector control. At each point in time, the methods calculate how to optimally energize the motor based on current and voltage vectors. Depending on the concept and the required control dynamics, the control methods are based, in simple terms, on the voltage curve in the stator or the current curve in the rotor. In addition, the controllers require a control strategy that influences the motor behavior.

Automatic engine adaptation is the key

The big unknown for the inverter when operating motors is the motor data. In addition to entering the motor type, the nameplate data is sufficient for safe operation. They not only provide information about the speed associated with the frequency, they also specify limits that the user must observe during operation. For example, the current is not only used to determine the torque. The inverter must also limit it to avoid overloading the motor.

Nameplate data for three-phase asynchronous motors are familiar to many users and do not present a programming challenge. The handling of nameplate data for PM motors is more difficult. On the one hand, the user is often unaware of the data and its purpose, and on the other hand, engine manufacturers sometimes specify the data differently.

For a really optimal control of the motor, the input of the nameplate data is not sufficient in this case.

The reason: each manufacturer uses different material, their motors are subject to manufacturing tolerances, require different magnetization, and even certain motor data is interpreted differently by manufacturers. In addition, the motors are designed for different operating points. All this affects the so-called extended motor data, which in turn affects the quality of the motor control, since the points have an influence on the current/voltage values that the motor needs for optimal operation.

For an independent manufacturer of drive technology such as Danfoss, this means in practice that it must compensate for or eliminate precisely these variances in its devices. For this purpose, Danfoss relies on Automatic Motor Adaptation (AMA). The frequency inverter measures the connected motor at standstill. The measurement procedure for three-phase asynchronous motors, which has been available for years, has now been extended to include strategies for PM and synchronous reluctance motors. The procedure measures each motor within 3 seconds after entering some basic nameplate data. In this way, the motor always operates highly energy-efficiently and the user thus saves energy and reduces his costs.

Advantages for the user - one frequency inverter for all technologies

For the user, it offers great advantages to be able to drive all motor types with just one platform. Otherwise, he and the operator run the risk of having to use a very heterogeneous system landscape. In practice, this means more training for designers, operators and maintenance personnel. And warehousing for the different systems also drives up costs. It is therefore advantageous to be able to control all motor types with only one frequency inverter, as this significantly reduces the additional effort just described. Throughout the entire power range, plant operators can thus rely on uniform operation, the same interfaces, the same extensions, and proven, reliable technology. Spare parts inventory in their plants is simplified, as is maintenance, and training costs are reduced.