Does energy recovery make sense for your application?

Regenerative frequency converters make regenerative energy usable

Regenerative technologies feed braking energy back into the grid. This can be a very energy efficient approach. However, these technologies often entail higher investment costs. Additional energy losses may also occur due to poorer efficiencies, resulting in little to no energy savings. Therefore, always check whether the investment in regenerative units in your application pays off. Find out how in this Tech Insight article.

What is regenerative energy?

We encounter regenerative energy in everyday life – for example, when braking with a hybrid or electric car. When braking, the car’s electric motor becomes a generator and the braking energy flows back into the battery as electrical energy. This principle is the same in industrial applications.

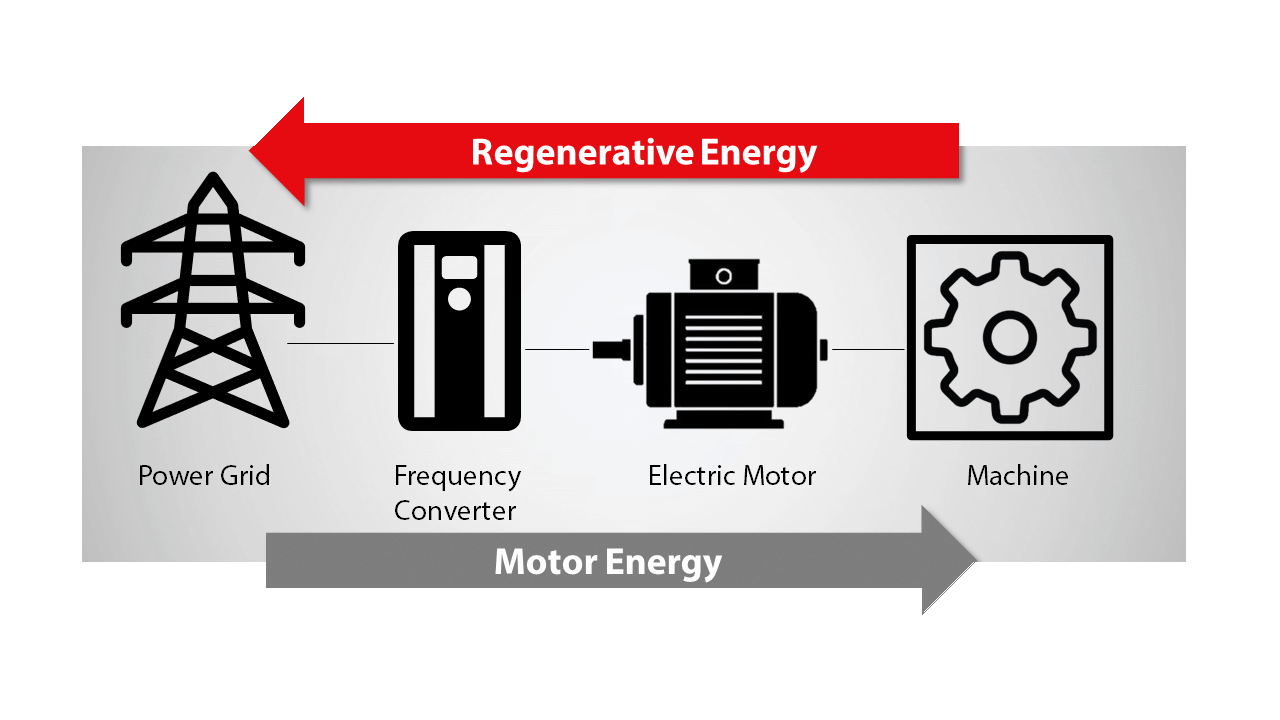

The energy flow in speed-controlled drive systems runs from the mains to the machine. A speed-controlled drive system consists of the following components: The grid supplies the power required to run the application. The frequency converter converts the constant voltage and frequency of the mains into variable quantities and supplies the motor with speed. The electric motor powers the application by converting electrical power into mechanical power. The machine converts the mechanical power into motion, material transport or pressure, for example.

In regenerative operation, all physical processes act in the opposite direction. This means that at certain operating conditions, energy flows return from machine to frequency converter.

When does regenerative energy occur?

A machine generates regenerative energy in certain operating states, such as during deceleration processes of centrifuges. This reduces the speed of the machine and the kinetic energy previously absorbed is released. The lowering of a hoist or elevator also represents such an operating condition. Here, the potential energy that was previously absorbed when lifting or holding the load is released again.

If a braking process takes place in an application with an electric motor, such as when an elevator decends, then regenerative energy is generated that can be fed back into the grid.

The energy emitted by the machine is absorbed by the electric motor, which now acts as a generator, and converted into electrical energy. The more frequently these operating conditions occur, the more frequently the motor runs as a generator and the more regenerative energy can be fed back.

Part of the energy is lost as power dissipation due to the mechanical work of load and friction. The remaining part enters the circuit of the frequency converter via the motor. The typical design of frequency converters prevent the flow of energy from the converter to the mains, therefore the energy is usually converted into heat and dissipated to the environment as power loss. However, various regenerative technologies can be used to harness feed regenerative energy into the grid.

Handling of regenerative energy

Let’s first look at methods where regenerative energy remains unused and is dissipated, but where there is little or no capital cost.

- Motor as braking resistor: The motor itself acts as a braking resistor and absorbs the energy as thermal energy. The basic principle here is based on a re-magnetization of the motor. However, if the regenerative energy is too high, the motor can easily overheat, creating the risk that the motor will be damaged and fail.

- Brake chopper with braking resistor: Brake choppers with braking resistor are one of the more common methods in use. This process is also subject to the principle of converting energy into heat. The brake chopper is a semiconductor switch that pulses the DC link voltage to a braking resistor, creating a clocked current flow in the braking resistor. This current flow generates heat through the ohmic resistance of the braking resistor, which is dissipated to the environment.

How to use regenerative energy

In practice, there are two common technical solutions as an alternative to methods where braking energy is lost. Those methods make regenerative energy usable. Both technical solutions are possible with Danfoss frequency converters.

- DC link coupling by frequency converter with active rectifier: This type of frequency converter can connect its DC link to the DC link of other devices. This makes it possible to supply other devices directly with the regenerated energy. However, there are some limitations to consider. For example, users should ensure that a short circuit in one device cannot damage other devices. In addition, it is necessary to consider the consequences of all coupled devices emitting generator-generated energy at the same time.

- Feeding power back through regenerative frequency converters: Frequency converters with Active Front-End or Active Infeed Converter can feed regeneratively generated power back into the power grid. These devices require a higher initial investment. Whether these devices are economically reasonable to feed back energy into the grid, depends on three factors.

Regenerative frequency converters: When is the investment economically reasonable?

With regenerative frequency converters, regenerative energy is not lost but used. This improves energy efficiency. However, compared to non-regenerative frequency converters, regenerative frequency converters have poorer efficiencies and correspondingly much higher losses. Therefore, please check for each application whether the regenerative energy can compensate for the losses and whether the increased investment in a regenerative frequency converter is economically reasonable. Economic efficiency of regeneration can be determined by the following three factors:

- Amount of available regenerative energy: Most applications generate energy during deceleration processes. This energy decreases continuously during the speed reduction. Theoretically, the regenerative energy is equal to 50 percent of the difference between the energy that is in the system at the beginning of the braking process and the energy that is in the system at the end of the braking process. In reality, however, this figure is somewhere between 10 and 20 percent. Elevators, cranes and hoists being the exception.

- Load cycle and proportion of time of regenerative operation: The more often a motor runs in regenerative mode, the more energy it can feed back into the grid. Therefore, the states in the load cycle that generate energy must be determined. A load cycle is defined, for example, by the propotion of time of lifting (motorized operation) and lowering (regenerative operation) of a hoist.

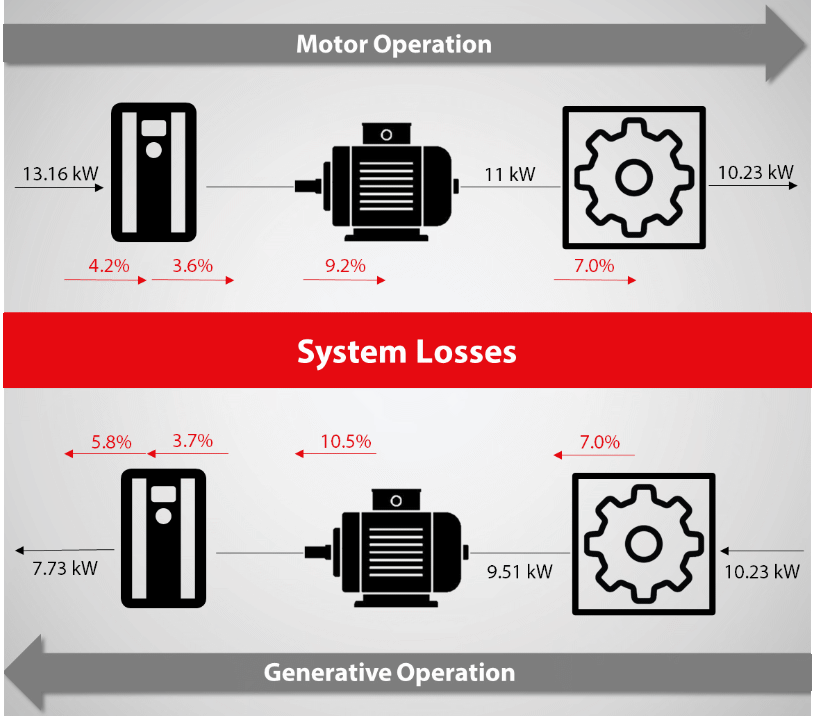

- Losses: The motor, cables, gearbox and even the regenerative device itself generate losses that reduce the energy that can be returned to the grid. The losses of the regenerative frequency converter are much higher than those of a standard frequency converter. This is because they use an active rectifier whose losses can be twice as high as a normal rectifier, both in operation and in standby. Depending on the design, regenerative frequency converters without necessary filters generate more harmonic disturbance, which can also lead to higher losses in the network.

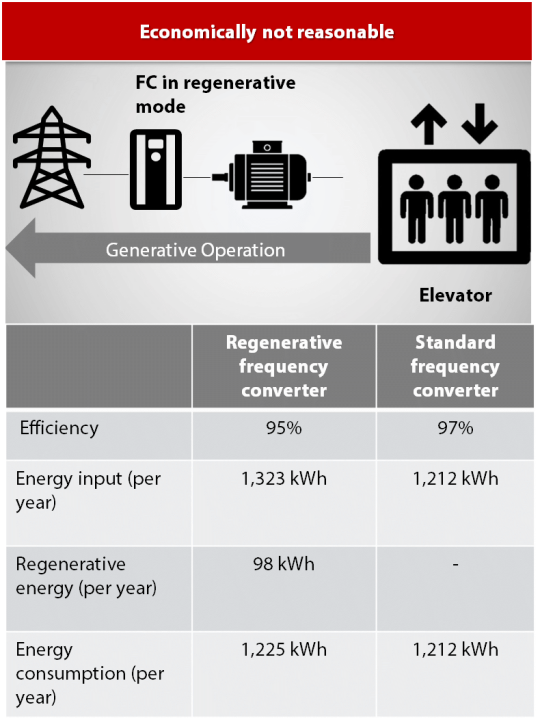

For an elevator, the calculation shows that the use of braking energy is not economically reasonable.

In elevators, regenerative energy is generated when the elevator moves downwards. Nevertheless, the use of regenerative frequency converters does not pay off because the proportion of time in regenerative operation is too short. The regenerative energy can therefore not compensate for the additional losses of the regenerative converter. There can be no savings from regenerative power. The energy consumption is lower with a standard frequency converter.

In the online tool, you can learn about these facts in a playful manner. There you will discover the hidden energy efficiency champions in your building and check where energy recovery is economically reasonable.

The building shown is based on Danfoss production site in Graasten, Denmark. All value quantities of the savings and the related calculations are related to the dimensions of this building. Start your energy efficiency match now!

The second examples shows an indoor crane. The proportion of time of regenerative operation is high. Energy savings are achieved through regenerative technology. In the example calculation, this can save around 210 euros a year in energy costs. Accordingly, the investment pays for itself after just four years, and even faster if energy prices are higher.

Each plant is, of course, to be considered individually. Do you operate a hoist, an elevator or a centrifuge in your plant? Want to know if regenerative energy recovery makes sense for your applications? Contact a Danfoss expert for a personal checkup.

Is it worth it? In addition to energy recovery, there are other measures to save energy, costs and emissions in the building. Examine the return on investment of energy efficiency investments. Which investments pay off? Which measures pay for themselves comparatively quickly? Learn in detail how to calculate the return on investment (ROI) of energy efficiency investments in this article.

Discover your energy efficiency champions!

Energy is and will remain expensive. In addition, companies must reduce CO₂ emissions as part of their ESG targets. Many companies therefore invest in renewable energies such as photovoltaics on the roof or purchase green electricity. But is that enough? Discover the hidden energy efficiency champions in your building with the new online tool. You will learn which settings will save you the most energy, costs and emissions at the same time. By the way, the example building in our online tool has the same dimensions as the Danfoss production site in Graasten, Denmark. All value quantities of the savings and the related calculations are related to the dimensions of this building. Start playing your energy efficiency match now!

Talk to experts

Where can energy recovery be used sensibly in the building? Whether it’s a new construction project or an existing building, commercial buildings need to ensure a precise balance between dynamic growth and sustainable management. Whether in hotels, offices, data centers or public facilities, Danfoss products and drive solutions can help you achieve significant energy savings, emissions reductions and cost reductions. We support you with expert advice on specific applications and on holistic solutions for optimum efficiency in your building. Do you have questions about energy efficiency with drive technology in your building? Then simply book an appointment in the online expert calendar.