A separator is a device for separating two or more liquids or solids. It is frequently used in water treatment, waste water recycling and food processing. They work either by gravity or pressure. The particles are normally collected on a special filter element, which then needs to be cleaned regularly to maintain high performance. Separators can also be used to separate or concentrate emulsions.

Separators are suitable for separation tasks that require high selectivity or where the separation of very fine particles is important. They are also used in the separation of solid-liquid mixtures with low density differences. Disc separators can be used for a wide range of applications and can be found in various industrial sectors. Among them:

- In the food and beverage industry

- In the chemical, pharmaceutical and biotechnology industries

- Environmental protection

- In the petroleum industry and energy production

- In the grease and oil processing industry

In practice, separators are used for three different separation processes.

- The separator is used as a clarifier to separate finely dispersed solid particles from a liquid. A typical example is the clarification of cloudy substances from fruit juice.

- As a purifier, the separator separates a liquid with a low density from a liquid with a high density, for example the separation of water droplets from mineral oil. Separation of solids is also possible.

- The separator is also used to concentrate liquids. This refers to the separation of a light liquid from a heavy liquid or the separation of two solids, for example the extraction of essential oil from water.

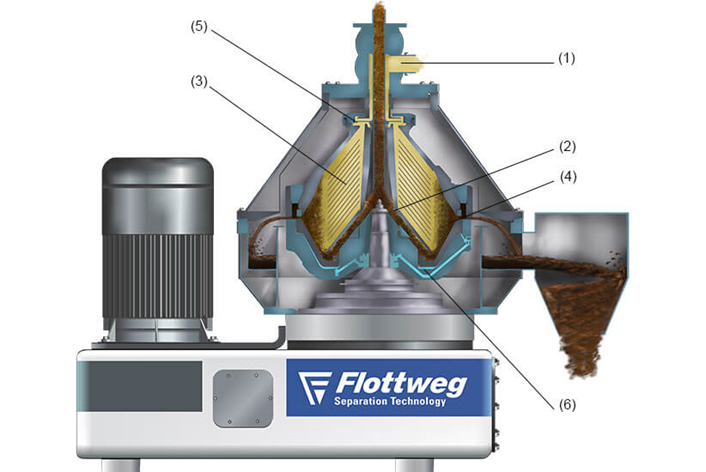

Structure of a disk separator

- Inflow

- Cylindrical drum

- Plate package

- Solids compartment

- Peeling disk

- Outlet

How a plate separator works

- The mixture to be separated enters the distributor of the rotating drum via a stationary inlet pipe.

- There it is accelerated to the peripheral speed of the separator bowl. It is important that no unnecessary shear forces occur when distributing the mixture, which could break up the fine particles or create emulsions.

- The solids are forced outwards and collect in the solids chamber.

- The separated liquid phases flow through the disk stack into the upper part of the bowl, where they are discharged via a peeling disk.

- The hydraulic emptying mechanism opens the separator at the outermost solids collection area of the centrifuge housing.

- After the solid phase has been discharged, the separator closes again.

This process takes just a few tenths of a second.