New EU requirements:

May I continue to operate my engine?

Episode 8

New requirements for engines in the EU

As of July 1, 2021, new requirements for motors and frequency converters apply in the EU for ecodesign. This logically raises questions: Are existing engines still allowed to be repaired and used? Do IE3 motors fit into existing machines? Do the costs of the motor and converter increase with the efficiencies? Markus Kutny from Bauer Gear Motor and Michael Burghardt from Danfoss Drives answer these and other questions in a podcast conversation. Both agree that a systems approach is needed to leverage further savings potential – but that will be difficult.

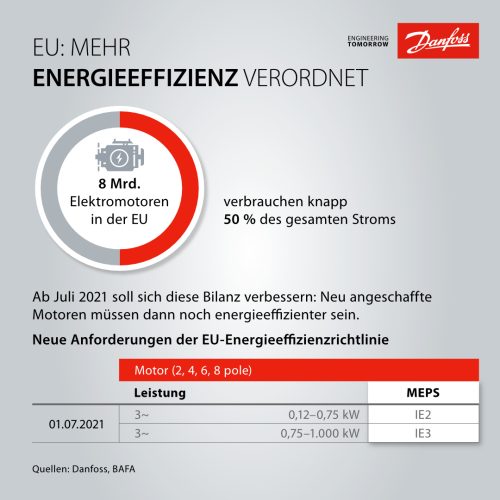

The background: More energy efficiency prescribed for engines

There are currently about eight billion electric motors in use in the EU, consuming nearly 50 percent of the electricity generated in the EU. With a wide variety of applications, sizes and technologies – from small motors for running cooling fans in computers to very large motors for heavy industry – the sector is very heterogeneous. This is where there is great potential for energy savings, and this is precisely where the EU eco-design requirements for engines come in.

Motors, frequency converters and drive systems are classified according to their energy efficiency. The IEC 61800-9-2 standard defines IE classes for frequency converters and IES classes for drive systems (Power Drive System – motor and frequency converter combined). Since January 2015, it has been a legal requirement that new IE2 motors must have a frequency converter for operation in Europe. From July 2021, the minimum requirement for motor efficiency will be IE3, and from July 2023, the minimum requirement for motors in the 75-200 kW range will be IE4. For frequency converters, the minimum requirement from July 2021 is IE2. In this podcast episode, you’ll learn what users need to do to meet these requirements.

5 Questions on the EU Energy Efficiency Regulation for Engines

-

The good news up front, there was no panic buying before July 1, 2021. The grandfathering also contributes to this. Anything placed on the market by July 1, 2021, may continue to be used. However, manufacturers are not allowed to produce and then sell "old" engines after the deadline. The end customer is therefore on the safe side.

-

What is the user allowed to repair now? There is a good answer to this question as well: repairing existing engines is still allowed. For example, a defective bearing may be replaced and the motor may continue to be operated. To be noted: For smaller engines, the repair effort may no longer be worthwhile.

-

Does an IE3 motor still fit into existing machines? In order to achieve the IE3 efficiency targets, motor manufacturers sometimes have to adapt materials, for example use rotors made of copper. Depending on the existing plant, things can get tight(er).

-

Will engines become more expensive? Yes, IE3 motors can cost more because manufacturers use new, more efficient materials. However, this is not necessarily a reason to fear rip-offs: The EU regulation applies equally to all manufacturers, who adjust their materials based on it and may pass on additional costs.

-

Are users still allowed to use IE1 motors in intermittent operation? Yes, in this case the standard does not apply. Are there any other exceptions? Motors <20W and motors that do not comply with certain voltage ranges (1000V) are exempt from EU eco-design requirements. Submerged motors and unventilated motors are also excluded.

Scrapping drives?!

This also closes the circle to further drive podcast episodes: In Episode 2 "Scrapping Drives", Markus Lempp and Michael Burghardt from Danfoss Drives talk about German politics, who can get the money from the stimulus packages for a green reboot in Europe, and how the implementation of the EU Energy Efficiency Directive works.