The NTT data center in Frankfurt has one goal:

Saving energy while cooling

The amount of data worldwide is increasing exponentially. As a result, the market for data centers that process and store this data is also booming. Modern data centers require powerful cooling systems due to the extreme packing density of servers with their high heat loss. Both energy supply and cooling are critical factors for the safe operation of such plants. The EU-wide requirements for greater efficiency are forcing operators to rethink: energy consumption in cooling must be drastically reduced!

By loading the video, you agree to YouTube's privacy policy.

Learn more

Take the virtual tour

NTT’s data center campus, Frankfurt 1 Data Center, is one of the largest locations for data backup, colocation services to complex IT applications and cloud solutions with 60,000 sqm of data center space. The buildings are specially built and equipped for being used as data center. The location is ideal because of the maximum security and availability of infrastructure here. Important aspects were, above all, the secure provision of energy, simple connection to data networks and protection against natural hazards. To meet high customer demand, NTT Global Data Centers EMEA GmbH operates three additional sites in the Frankfurt region alone, which can provide additional space of over 50,000 sqm.

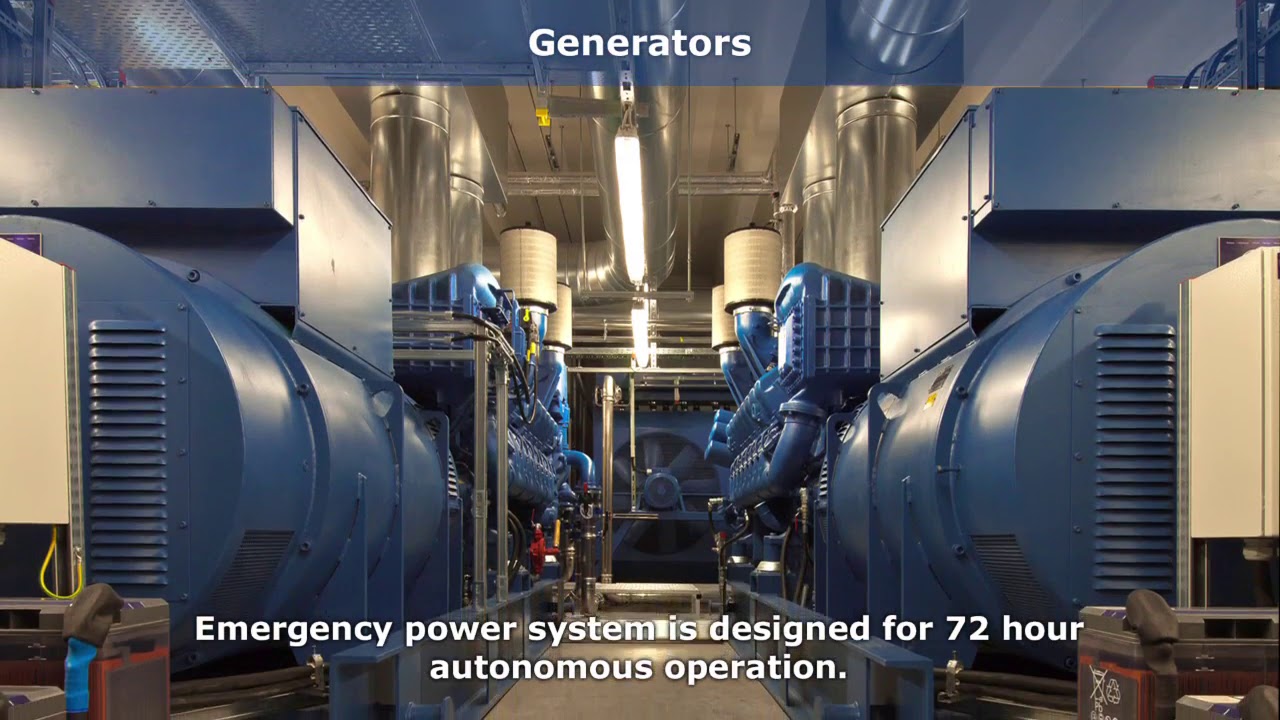

The challenge: Design energy-efficient cooling processes

One of the biggest challenges for NTT, in addition to the continuous and secure power supply, is the enormous waste heat from the servers running around the clock 365 days a year: In addition to the redundant power supply with additional emergency generators or buffer batteries, extremely reliable and equally efficient cooling of the computer cabinets and all other critical areas is therefore necessary. On average, each kilowatt of computing power requires 0.2 to 0.5 kW of cooling power, and the necessary cooling systems are correspondingly large. To make the cooling process as safe and efficient as possible, NTT in Frankfurt relies on a cooling system for the IT equipment with a central chilled water circuit for distribution within the building. Among other things, AC Drives from Danfoss Drives are used. The sophisticated concept covers every area from cooling air flow within the server rooms to the release of thermal energy into the environment.

Safe cooling at NTT: This is how it works

Christian Tietz, Sales Engineer at Danfoss Drives, explains step by step how the technology that cools the NTT data center works. Listen in and discover how AC drives handle pump control. Since the systems were first commissioned in 2003, they have always ensured the optimum flow rate and controlled the motor speed of the pumps using a differential pressure measurement. In this way, they permanently supply the consumers with the required amount of cold water.

The plant has both recooling units, which release waste heat or supply cooling water via the outside air, and chillers that can be switched on if the difference with the outside air is not sufficient during warm periods. The switching on takes place in stages in order to cool as energy-efficiently as possible. In the cold season, the outside air is often sufficient.

In addition to the frequency converters of the VLT series for cold and chilled water pumps, NTT in Continental Europe has been using Danfoss Turbocor exclusively as compressors in the installed chillers for about 2 years, in order to be able to benefit from the stepless speed control of the installed converter here as well. The resulting significant improvement in part-load efficiency is one of several factors that prompted NTT to take this step.

More than 100,000 hours of operation without failures at NTT

The AC drives used optimize the running time of the pumps by changing the lead pump or the follower pumps according to the operating time. All components of the refrigeration system are connected to a control center via Modbus and are centrally controlled by it. This also allows the operating personnel to monitor the operating states of the individual system components at any time. If communication between the control center and the AC drive should ever fail, the AC drives automatically switch to a maximum rated fixed speed to ensure cooling of the servers in any case.

NTT has been using Danfoss technology in Frankfurt since the data center was commissioned in 2003: In addition to the VLT HVAC Drives FC 102, VLT 6000 are still in use in some areas of the facility. According to the operator, they have probably run for around 100,000 operating hours – without ever causing any problems. The typical power ratings used are 11/15 kW up to 37 kW on the order of about 60 variable frequency drives per building – 500 to 600 in total.

How to implement ESG in companies?

All episodes of the podcast season at a glance

In the podcast season "Implementing ESG in your company: What to do now?" we go on an ESG journey. For this purpose, we have again invited numerous experts.

‘ESG’ stands for Environmental, Social and Governance. ESG was formerly known as corporate social responsibility. In episode (1/4), tech podcaster Robert Weber reflects on ESG: "For me, ESG has always been something that is pushed by the European Union. It’s a real bureaucratic monster that makes life difficult for companies. Talking to this season’s guests, it turns out I was wrong."

Dr. Christopher Scheubel from cubemos and Marie Hammer from Danfoss explain in episode (2/4) what ESG stands for and what tasks are associated with it in companies. They agree that ESG is an opportunity for companies. Because now everyone has to strategically address issues like supply chains and energy consumption.

Anyhow, despite all opportunities, ESG also challenges companies. The topic is new, many processes have not yet been defined. Larisa Xanthopoulou and Michael Wassermann from Danfoss Drives explain in episode (3/4) how Danfoss is dealing with this challenge and offer some insights into the company’s ESG journey. "We focus on transparency and learning by sharing data and insights with our customers."

Practical advice is shared by Christine Twellmeyer and Jesper Therbo from Danfoss in episode (4/4). Christine advises in-house around measures for more energy efficiency at Danfoss sites, while Jesper shows customers and partners how to save energy and emissions in buildings with drive technology.

EU Commission: CO₂ neutrality for data centers by 2030

Keyword: decarbonization. In the EU, data centers are to be climate-neutral by 2030, i.e., operated in a 100% CO2-neutral manner. The EU Commission has already been calling for this since 2020. To achieve this ambitious goal, even greater energy efficiency is needed in the processes, consistent reuse of waste heat, and an energy supply fed by renewable energies.

Data center cooling plays a crucial role in this. Due to its high energy consumption, it is also a main starting point for CO2 savings. Efficient cooling also saves CO2 with every kilowatt hour of power not consumed. If the resulting waste heat is then used sensibly, everyone benefits in the end. It’s good to know that data centers have huge potential for waste heat recovery. Instead of being discharged to the outside environment, waste heat can be fed into the district heating network, for example, and used to provide heating and hot water for neighboring communities.

The technology for this already exists and is proving itself in numerous applications in daily use. Learn more about heat recovery and heat reuse in data centers.

Model region Rhine-Main

The Rhine-Main region in Germany is considered the most important data processing location in Europe, alongside the British capital London. A good 60 data centers are located here. It is therefore hardly surprising that the first waste heat utilization projects via the district heating network are emerging in this region. The carrier for the waste heat is the cooling water of the data centers, which heats up due to the heat loss in the rooms. But in order to fully exploit the potential of data centers at this point, in many cases it is first necessary to switch from air to water cooling of the computers. This is because an air cooling system usually releases the waste heat directly into the outside air.

Numerous practical examples show that the use of waste heat in the district heating network can work well. One of them was created in Nordborg, Denmark. In the podcast episode "Energy crisis – incentive for more efficiency? Episode (2/4)" you can learn more. From around minute 7, Helge Vandel Jensen from Danfoss Drives explains what Danfoss is doing for its own CO₂-neutrality and how this involves using waste heat from Danfoss’s own data center at its Nordborg headquarters in the district heating network of the nearby municipality. Listen to the podcast episode.

Energy crisis - incentive for more efficiency?

All episodes of the podcast season at a glance

In the podcast season "Energy crisis – incentive for more efficiency?" we go on an energy efficiency journey – from green hydrogen to storage technologies and DC supply in industry. For this, we have invited lots of energy experts. They explain how the industry must position itself technologically for the next few years and what should be done in terms of energy policy.

In episode 1/4 of the season, you might want to listen to podcast host Robert Weber. He wonders how we could have slid into the current situation – when technologies and also political incentives for more energy efficiency and the use of green energy have been available for a long time. In the process, he lets guests from the previous podcast episodes have their say again on the topic of energy and innovation.

Episode 2/4 of the Energy Crisis Relay welcomes Sebastian Weckmann, Head of the Industrial Energy Systems Department at Fraunhofer IPA, and Helge Vandel Jensen, Director Business Development Electrification at Danfoss Drives, two absolute experts in new ways of industrial energy supply. What energy sources can we use in the future? How quickly can we succeed in this transformation process? What can industrial companies do now? Episode 2/4 provides answers to this.

The whole world is talking about green hydrogen: In episode 3/4 of the season, host Robert Weber also talks to Jochen Bard from the Fraunhofer Institute about this special energy carrier. Will Europe become the hydrogen champion through self-production? Or will we import green hydrogen? If so, from where and how can it be transported? Danfoss expert Damir Alihodzic complements with expertise around the hydrogen production, the so-called electrolysis. He knows what technology goes into the big electrolysers and shares that knowledge with you in the podcast episode.

Last but not least, the season finale with Egon Schubert from Innofas and Reiner Kaiser from Danfoss Drives offers a very good and deep insight into the world of decentralized storage technology. What about the stability of our power grid? What can storage facilities contribute here? How and, above all, how quickly can companies integrate decentralized storage? That’s what host Robert Weber discusses with his guests in this episode.

You like Torque – The Drive Podcast? Then subscribe to it on Spotify or Apple Podcasts.

Excess heat is the world’s largest untapped source of energy

Did you know that excess heat is the world’s largest untapped source of energy? Every time an engine runs, it generates heat. Anyone who has felt the warmth behind their fridge can confirm this. The same is true on a larger scale in data centers and other commercial buildings. Good to know that we can reuse excess heat to supply, for example, a factory with heat and warm water or reuse it in neighboring homes and industries through a district energy system.

In the EU alone excess heat amounts to 2,860 TWh/y, corresponding almost to the EU’s total energy demand for heat and hot water in residential and service sector buildings. Reusing it for such purposes, is energy efficiency in its purest form.

Learn more about this topic in the new Danfoss whitepaper.